How to Calculate Mazzei Injector Size

How to Calculate Mazzei Injector Size

Guide to Injector Performance Tables

Guide to Injector Performance Tables

Mazzei Water Injector Peformance Table

Mazzei Water Injector Peformance Table

MAZZEI VENTURI INJECTORS

DESCRIPTION

Mazzei® venturi injectors are differential pressure injectors with internal mixing vanes. Superiority of Mazzei injectors is due to the unique, patented design which maximizes injector efficiency, suction capacity and mixing capabilities. The operating costs of Mazzei injectors are lower than less efficient systems, and Mazzei injectors are trouble-free because they have no moving parts.

HOW A MAZZEI VENTURI INJECTOR WORKS

When pressurized water enters the injector inlet, it is constricted toward the injection chamber and changes into a high-velocity jet stream. The increase in velocity through the injection chamber results in a decrease in absolute pressure, creating a vacuum, thereby enabling an additive material to be drawn through the suction port and entrained into the water stream. As the jet stream is diffused toward the injector outlet, its velocity is reduced and it is reconverted into lower pressure energy.

APPLICATION

The highly versatile Mazzei Injectors are suitable for a wide variety of applications.

- Agriculture

Ag Irrigation Systems - to inject fertilizers and other chemicals or water treatment additives.

Ag Spray Systems - for mixing and/or the transfer of concentrated pesticide materials.

Food Processing - for water chlorination, injection of detergents,bacterial agents, other water treatment purification additives. - Home and Garden

Irrigation Systems - for application of liquid fertilizer through landscape sprinkler or drip irrigation systems, hose end sprinklers and/or spray nozzles. (Check Local codes for backflow device requirements) - Industrial/Commercial

Water Treatment - to inject air, liquids, gases (ozone), and other water purification chemicals for cooling tower or other water or fluid recirculatory systems, waste water systems, potable water systems.

Washing & Cleaning - to inject detergents, solvents, and other cleaning agents into carpet cleaning equipment, car wash systems, dishwashing equipment and other industrial cleaning processes.

FEATURES

- Molded from high quality thermoplastics with superior strength, high temperature capability, resistant to most chemicals.

- No moving parts, low-maintenance trouble-free operation.

- Unique design allows maximum cavitation in the injection chamber, thereby providing instantaneous

- Ideally suited for continuous mixing functions, require no secondary blending devices.

- Initial cost and installation cost are low

- Powered by the motive fluid, no external energy required for most installations.

- Available in a broad range of sizes, flows and injection capacities.

TYPICAL INSTALLATIONS

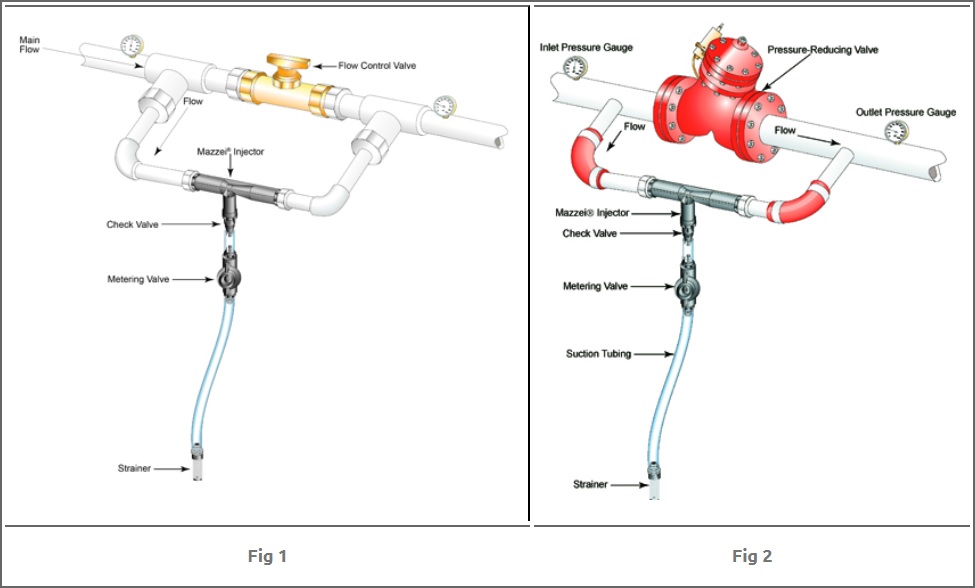

The injector is installed around a point of restriction such as a regulator valve or a gate/ball valve to create a differential pressure across the injector. This allows the injector to produce a vacuum and draw in material. (See Fig.1 and Fig.2)

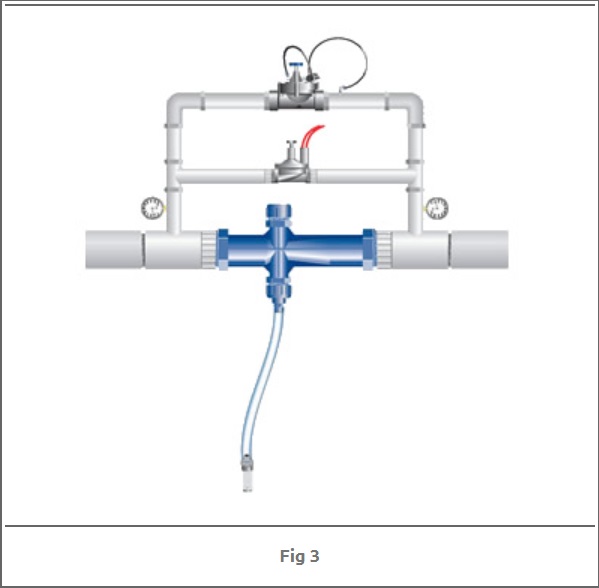

The injector is installed on the mainline and the pressure reducing device is on the bypass. Chemical injection can be turned on when the control valve is closed. When the valve is open, injection stops due to reduced pressure differential. (See Fig.3)

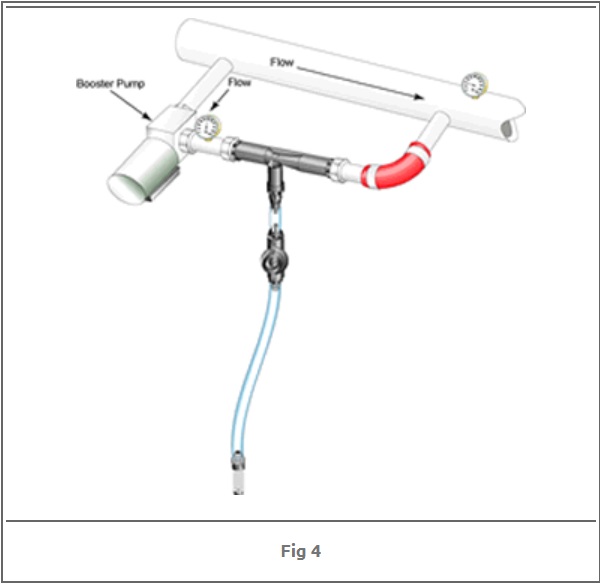

The injector is installed on a bypass with a booster pump. When mainline pressure cannot be reduced, a small booster pump can be used to create sufficient differential pressure to operate the injector.(See Fig.4)

- Model: HR1583A

- Shipping Weight: 2kgs

- Manufactured by: Mazzei